Boondocking for 17 Days in a Diesel Shop Parking Lot

This note is going to be a little different because it’s about a repair to our own camper performed by someone else. I’m going to be pretty specific about some of the details, but before you bounce off the article, know that the reason this repair took 17 days was solely the fault of our aftermarket warrantee company and their repeated attempts to get us to pay for this expensive repair ourselves.

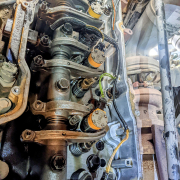

I’m going to resist the urge to launch into a technical expose of the rig, the leaky injector harness socket, and the sticky injectors which caused us to need thousands of dollars of repairs on the engine. I’ll keep it to two main points, instead.

The first point is if you have no choice but to let a motorhome sit, you should just sell it. Some people will take exception to this, but these things are made to roll. (If it’s a long-term spot at a campground, you’d probably be happier with a fifth wheel or park model anyway.) Both the leaky injector harness and sticky injectors, which both happened right around 100k miles on the odometer, were way too soon for this type of engine. According to a two different master diesel mechanics, the problem was sitting for well over a year at some point in the motorhome’s existence before we acquired it. A sit that long allows all the oil drain out of the engine. There’s more to the chemistry, but that’s the layman’s version. The consequence was the seals shrinking and cracking on the wiring harness and the injectors developing considerable mechanical and hydraulic resistance.

What is the right way to address “exercising” a motorhome engine when you’re stationary for a long time? Most diesel engines consider starting more than 36 hours after being turned off “extreme operating conditions”, so from a certain standpoint, recreational use will never be enough for the design of these big motors. If you’re going to start them up, once every month seems to be the interval to keep them oiled enough to be shelf stable as long as the starting temperature of the block and the outside air temperature are both above 40 degrees. Starting them more often than that, if they’re stationary, is just more instances of “extreme operating conditions”.

Starting them when they’re really cold should just not be done unless it’s time to get on the road. If you’re going to start it, let it come up to temperature. To get a diesel up to temperature, you’re going to have to use the high-idle function of your cruise control. The trick is to let it low idle until the oil pressure comes down to just above the normal operating level (on ours, to 50psi). Then bump it and wait on the pressure to come down again. Most big diesels need to turn at least 1200 RPM to avoid damage to the turbo and injectors. A mechanic actually recommended our Caterpillar C-9 turn 1400 RPM at idle. The problem with idling low is “glazing” – the build up of varnish from incompletely burned diesel passing through the cylinders, valves, and especially the turbo charger. Long story short, just bump up the idle as soon as the oil pressure is low enough to not stress the system.